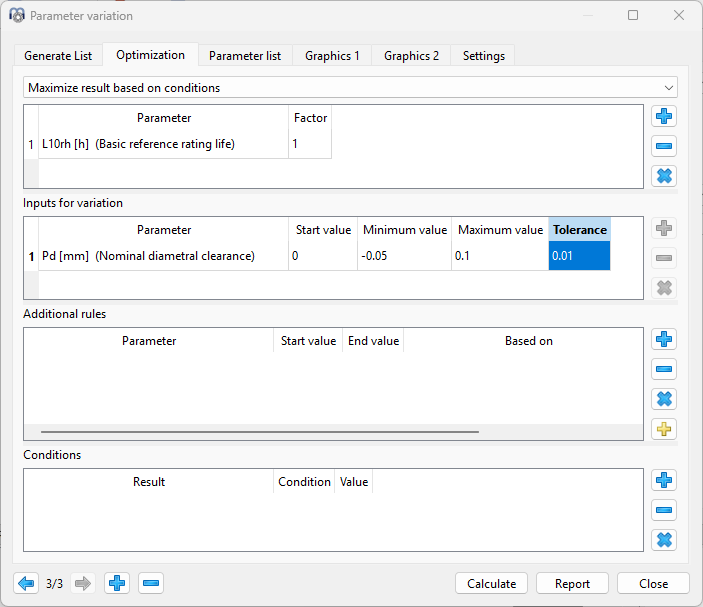

Optionally an optimization step can be used. Different options are available for the optimization of one input parameter.

•An input parameter can be maximized or minimized based on conditions

•A result parameter can be maximized or minimized. The target to minimize or maximize is the sum of the results multiplied with a factor.

•The deviation of a result parameter from a target is minimized. The target function of the optimization is the sum of the squares of the deviation multiplied with a factor.

For the example before the radial force Fy should be maximized to that L10rh=5000h is reached.

The conditions have to be fulfilled on the start value of the parameter. If this is not the case, the results are set to zero. If the conditions are still fulfilled at the maximum value, the calculation stops and the results are set to zero too.

Additional rules can be defined to set additional inputs based on optimization parameter. The additional inputs are interpolated between start value and end values dependent on the optimization parameter between start value and maximum or minimum.

The results for the radial force Fy in below image show an error for small clearance as the 5000h cannot be reached.

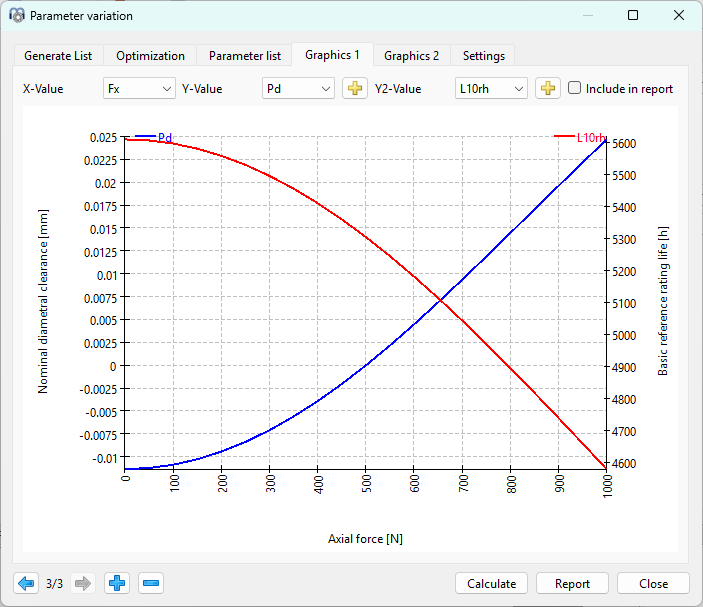

Another example shows the optimization to maximize a result. The clearance is chosen by the software for multiple axial loads to maximize the bearing life:

The factor is used to scale the result value and should be increased for very small targets as the internal tolerance is fixed to 10-4. The tolerance for the parameter is used by the solver and should be related to the required accuracy. The additional inputs are interpolated between start value and end values dependent on the inputs for variation between minimum and maximum value.

The results are shown as graphic: