For ball bearings and radial cylindrical roller bearings, the shoulder diameter of inner and outer ring can be defined. For tapered roller bearings, the shoulder for the inner race can be defined. If an input of zero is given, it will not be considered.

The shoulder diameter is compared to the maximum extension of the contact ellipsis. A warning is shown if the ellipsis would extend above the shoulder. The Hertzian stress is not valid in that case.

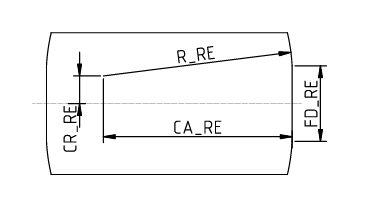

The required shoulder diameter is shown in the report together with a length ratio eLR_i, eLR_e which is showing a safety of shoulder length. The length ratio is defined as the length from lower end of contact ellipsis to shoulder (the green line the graphics) divided by the length of the contact ellipsis 2a (red line in the graphics). The value should therefore be larger than 1 or 100%.

For spherical ball bearings, the shoulder diameter of the outer race is limited by the radius of outer race and bearing width automatically if the bearing width is entered.

Instead of using an absolute value, the shoulder height can be defined using a percentage of ball diameters. A factor of 50% would be a shoulder up to the pitch diameter, so the factor should be between 10% and 40% for most bearing types. Using this factor allows to have a default geometry on changing ball diameter or pitch diameter.

For angular contact bearings the lower shoulder can be defined optionally. It has an influence on the bearing mass and on the interference fit in case an equivalent cross section is used for the interference fit.

For radial cylindrical roller bearings and tapered roller bearings, it is assumed that the axial force is acting at half the height of the shoulder. A shoulder opening angle can be defined. A value of 0° means the force is acting parallel to the axis of the roller.

For radial cylindrical roller bearings and tapered roller bearings optionally a roller end radius can be defined. If this is done the contact position and contact stress is evaluated. A contact stiffness is used based on Hertzian point contact.